Views: 0 Author: Site Editor Publish Time: 2025-11-20 Origin: Site

DIN 7735 is a historic reference point for many resin-bonded laminates used in electrical insulation and light mechanical components. While the standard itself is now largely legacy, its influence persists across drawings, procurement lists and product datasheets. This guide focuses on practical understanding and clear, actionable steps you can use when you encounter DIN 7735 on a drawing or specification.

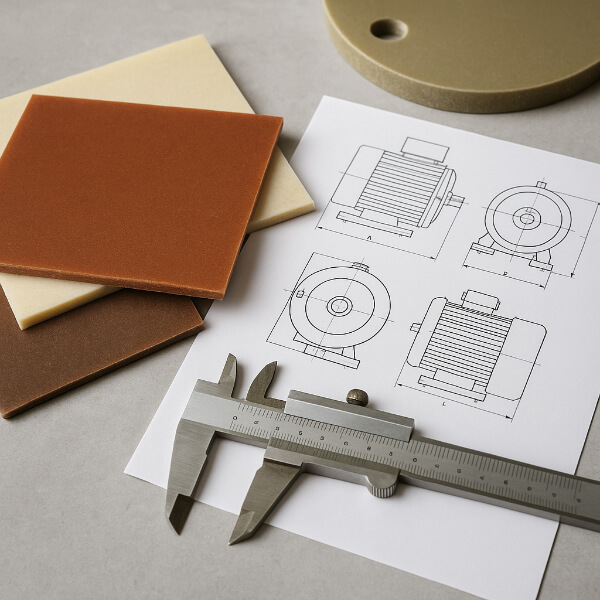

At heart, DIN 7735 is a naming and classification framework for laminates made by impregnating layers of paper, fabric or glass mat with a thermosetting resin and curing them under heat and pressure. The resulting boards and panels provide a balance of electrical insulation, dimensional stability and machinability. Engineers used DIN 7735 as a shorthand to describe the expected family of properties for a material without listing every single test value on a drawing.

Tip: Treat DIN 7735 like a family name rather than a single product — it groups materials with similar processing and property trends rather than guaranteeing a single set of numbers.

Paper-phenolic laminates: Economical, easy to work, generally used where heavy mechanical loads aren’t primary. Good for insulating washers, spacers, and mild structural components.

Fabric-reinforced phenolics: Cloth or fiber layers give better toughness and bending strength; used where parts need improved mechanical performance while retaining good electrical insulation.

Glass-mat and glass-reinforced laminates: Higher mechanical strength and better dimensional stability — chosen when structural stiffness or higher dielectric strength is required.

Each family brings tradeoffs: cost and machinability versus strength and moisture resistance.

Historically, DIN 7735 was published in parts: one part laid out test methods and performance expectations, while the companion part acted as the type table and designation guide. For most modern engineering work you only need to know that those two parts existed — the content has been absorbed into newer international standards and supplier practices. Mentioning these parts in a specification helps trace legacy material expectations but does not substitute for up-to-date datasheet verification.

Legacy drawings: Many product assemblies and service parts lists still cite DIN 7735. If you replace materials without mapping the specification, fit or performance can be affected.

Procurement shorthand: Suppliers sometimes still reference older codes on datasheets to help customers transition from historical specs.

Traceability: Knowing the legacy origin reduces guesswork when determining if a modern equivalent will meet long-term performance needs.

Identify the family and code on the drawing. Note whether the call-out implies paper, fabric or glass. If a sub-code is present on the drawing, capture it verbatim.

Define critical performance parameters for your application. Typical examples: minimum bending strength, maximum water absorption, working temperature, dielectric strength, allowed thickness tolerance.

Collect candidate datasheets from multiple suppliers. Ask suppliers to include legacy codes and to confirm the testing standard used for each property.

Compare values using consistent conditions. Verify specimen conditioning, test temperatures and units to ensure apples-to-apples comparison.

If a perfect match isn’t available, prioritize the property that affects safety or function. For electrical insulation choose dielectric and moisture performance; for structural parts prioritize flexural strength and impact resistance.

Document the chosen modern equivalent on the drawing. Replace the legacy reference with the modern grade plus a short table of key properties so future buyers won’t need to guess.

Nominal thicknesses and tolerances

Flexural strength and method used

Water absorption (conditioning and test duration)

Dielectric strength or breakdown voltage (test geometry and conditioning)

Operating temperature / glass transition if available

Recommended machining/finishing notes (edge sealing, hole drilling speeds)

A service team needs replacement insulating spacers for a legacy switchgear design that lists a DIN 7735 code. The team proceeds to: identify the spacer’s mechanical demands, request datasheets from three suppliers showing the legacy code, compare water absorption and bending strength at room temperature, choose the candidate that meets or exceeds both limits, and update the drawing with the supplier grade plus a 3-line property table. This removes ambiguity for future procurement and reduces the chance of early part failure.

Always treat DIN 7735 as a starting label — not a full specification. Modern procurement should rely on specific property values and current testing standards.

Secure at least one supplier test report or datasheet for any critical component that references a legacy code.

When replacing or specifying materials, list explicit property thresholds on the drawing so future engineers don’t need to translate legacy codes.