Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

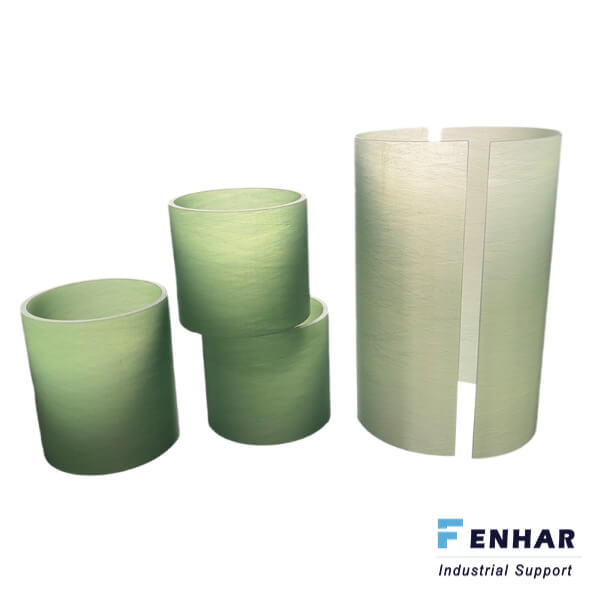

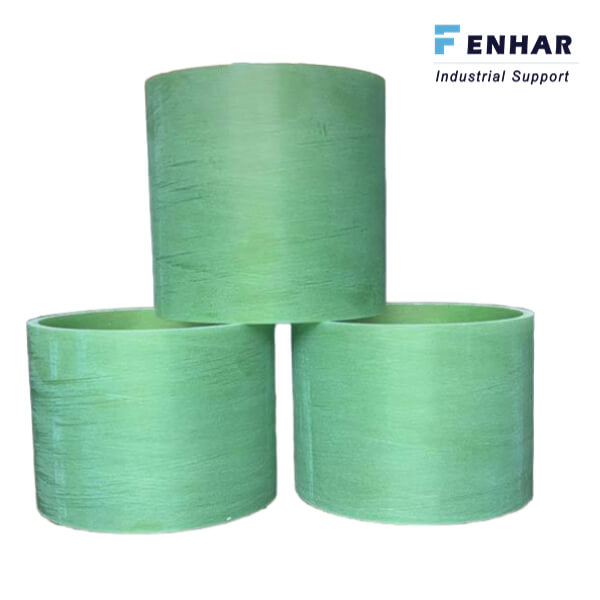

Epoxy resin filament wound tubes are a versatile class of composite cylinders engineered to deliver reliable electrical insulation while keeping weight and bulk to a minimum. Built by winding continuous reinforcement fibers around a rotating mandrel and consolidating them with an epoxy matrix, these tubes combine predictable mechanical behavior with stable dielectric performance — a balance engineers rely on when designing compact, long-lived electrical and structural systems.

The core of the process is a controlled filament-winding cycle: resin-impregnated fiber is laid in precise angles and layers to create a tailored laminate. Varying the fiber orientation (hoop, helical, bias) and the number of plies lets manufacturers tune stiffness, hoop strength, and through-thickness properties without changing the raw materials. After winding, parts are cured under specified temperature and time profiles to lock in resin crosslinking and dimensional stability. This predictable production technique reduces voids and ensures repeatable performance from part to part.

Mechanical strength: The oriented fibers provide high tensile and compressive capacity along preferred axes, with excellent resistance to bending and impact for thin-walled geometries.

Dielectric reliability: Properly formulated epoxy systems exhibit low dielectric loss and maintain insulating properties across typical operating temperatures.

Environmental durability: These tubes resist moisture uptake and many common industrial fluids; the epoxy binder also contributes to chemical resistance and UV stability when required.

Thermal behavior: Epoxy matrixes used in filament winding tolerate elevated temperatures and show modest thermal expansion, helping preserve clearances in electrical assemblies.

Filament wound epoxy tubes are chosen when designers need a compact insulating sleeve or structural tube that must withstand electrical stress and mechanical load simultaneously. Common uses include:

Insulating cylinders for medium- and high-voltage transformer components

Structural housings and bobbins for motors and generators

Lightweight, non-conductive supports in switchgear and power distribution equipment

Precision spacers and standoffs in high-performance electronics and test fixtures

One major advantage is customization: inner/outer diameters, wall thickness, and length are readily produced to order. After curing, tubes can be machined, drilled, tapped, or cut to tight tolerances to accept inserts or flanges. Surface finishes can be modified — smooth for sliding fits or textured for bonding — and additional coatings applied for enhanced chemical or UV resistance.

Reputable manufacturers carry out tests such as dielectric breakdown, water absorption, flexural strength, and dimensional inspection. When specifying insulation tubes, consider: resin glass transition temperature (Tg), required dielectric strength (kV/mm), allowable moisture absorption, and machining allowances. Ask about batch traceability and sample testing to confirm compatibility with your assembly processes.

Install with protectors or soft shims to avoid point loads that can induce micro-cracks. Use compatible adhesives and avoid solvents that attack the epoxy matrix. Periodic inspections for surface crazing or discoloration can catch early signs of environmental degradation before performance is affected.

Compare electrical insulation suppliers on material data sheets, sample availability, lead times, and their willingness to support custom layups. For critical or regulated applications, request test reports and, if applicable, compliance documentation tied to the electrical or aerospace standard relevant to your industry.

When your project demands an insulating component that also carries mechanical load, epoxy filament wound tubes present a balanced, engineer-friendly choice. Their manufacturing repeatability, customizable layups, and combination of electrical and structural performance make them a dependable option across power, transportation, and industrial markets.