Introduction

Electrically insulation materials are essential for safe and efficient electrical system operation.

Definition of Electrical Insulating Materials

These materials are substances that hinder the passage of electricity. Insulating materials prevent the flow of electrical current. These materials lessen the risk of short circuits or electrical leakage. They have high resistance to electrical conductance. Additionally, these materials insulate and safeguard electrical conductors, components, and equipment.

In this blog post, we will discuss the classification of insulating material in detail. Additionally, we also go through its properties, applications, and future challenges in this modern world.

Importance of Insulating Materials

These materials hold significant importance in various applications. Here are some key points highlighting their industrial significance:

- Prevent electric shocks and accidents.

- Safeguard delicate electronic components.

- Ensure reliable electrical insulation and isolation.

- Reduce the risk of electrical fires.

- Enable efficient power transmission and distribution.

- In industrial settings, soundproofing insulating materials can contribute to the reduction of noise pollution.

- Withstand harsh operating conditions, including temperature variations, moisture, chemicals, and mechanical stress.

- Ensuring long-term performance, lowering the frequency of replacements, and minimizing maintenance prices.

- Vital components in renewable energy systems, including wind turbines and solar panels.

- Resist corrosion in the presence of chemicals and aggressive substances.

- Insulation technology innovations drive efficient and sustainable electrical engineering solutions.

Properties of Electrical Insulation Materials

These electrical insulators have distinct properties that enhance their efficacy. Let’s explore these properties:

Electrical Resistivity

Insulating materials have high electrical resistivity. They hinder the flow of electric current. This property allows them to prevent unwanted electrical conduction. Thus, this property ensures electrical safety.

Dielectric Strength

This property helps to withstand a high electric field without breaking down. Dielectric strength, enables them to withstand voltage stress. Moreover, this property maintains the insulating character of these materials.

Thermal Conductivity

Insulating materials often have low thermal conductivity. This property helps them provide thermal insulation. It prevents the transfer of heat and maintains stable operating temperatures.

Mechanical Strength

These materials own enough mechanical strength to withstand physical stress and environmental factors. They are durable and able to resist deformation or breakage under mechanical loads.

Classification of Electrical Insulation Materials

The classification of insulating materials is based on their composition and properties. Here are the main classifications:

Organic Insulation Materials

- Thermoplastics: These materials can soften and re-harden upon heating and cooling. Examples include PVC, polyethylene, and polypropylene.

- Thermosetting Plastics: These materials undergo permanent chemical change upon heating. The resulting structure becomes rigid and durable. Illustrative examples encompass epoxy, phenolic, and melamine resins.

- Rubber: Rubber materials such as silicone rubber and neoprene. They exhibit excellent flexibility, elasticity, and resistance to moisture.

Inorganic Insulation Materials

- Ceramics: They offer high mechanical strength, excellent thermal stability, and resistance to chemicals. These materials find application in high-temperature scenarios, like insulating spark plugs, kiln furniture, and furnace tubes.

- Glass: Glass materials provide excellent electrical insulation, chemical resistance, and transparency. These materials find applications in electrical equipment insulators, including capacitors and transformers.

- Porcelain: Porcelain insulators exhibit excellent mechanical stability and valuable electrical insulation characteristics. They have resistance to heat and chemicals. These materials are used in power transmission and distribution systems.

Composite Insulation Materials

- Fiberglass: Fiberglass composites consist of glass fibers. These glass fibers are embedded within a matrix material usually epoxy resin. They are also known as garolite G-10 sheets. They offer a combination of high mechanical strength and electrical insulation. Furthermore, they are resistant to heat and chemicals.

- Epoxy Resin: These composites are formed by combining epoxy with fibers or fillers. They provide high electrical insulation, mechanical strength, and dimensional stability.

- Phenolic Resin/Paper-based: These composites consist of cellulose paper impregnated with phenolic resin. They offer good electrical insulation, mechanical strength, and thermal resistance.

Gaseous and Liquid Insulating Materials

These materials include oils, gases (such as sulfur hexafluoride), and air. They provide electrical insulation and cooling properties in electrical equipment. These materials also offer good dielectric properties.

Applications of Electrical Insulation Materials

These materials find extensive applications in various industries and sectors. Here are some critical areas of application:

Electrical and electronic equipment

Insulating materials are vital in the production of electrical and electronic devices:

- Computers

- Smartphones

- Appliances

- Circuit boards

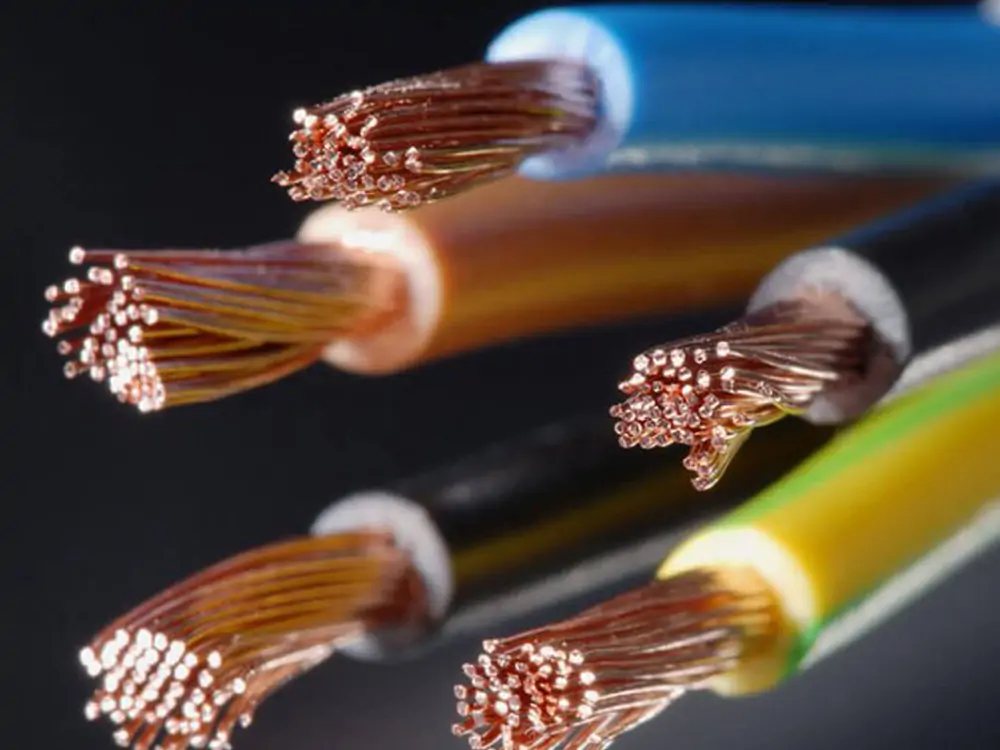

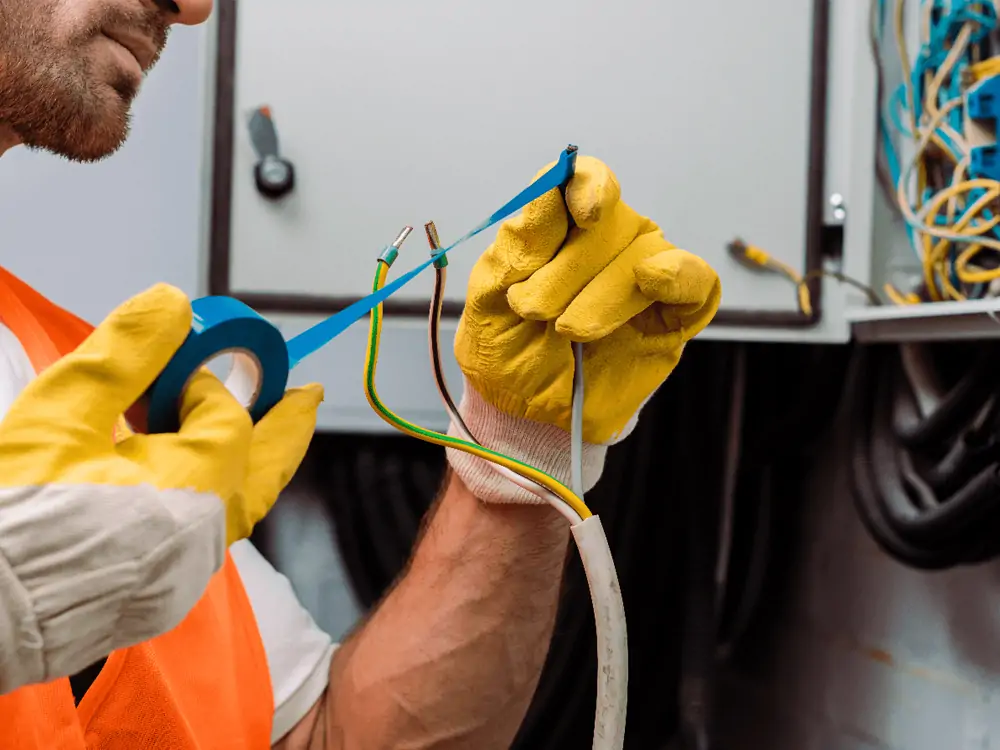

- Wire insulation

- Electrical switches

- Insulating coatings and Insulating sleeves

- Electrical laminates

Power Generation and Transmission

Insulation is essential for safe and efficient electricity transfer in:

- Power generation plants

- Transformers

- Electrical enclosures

- Substations

- Overhead lines

- Transmission lines

Insulation in Buildings

Insulating materials used in various applications, Such as:

- Electrical wiring and cables

- Circuit breakers

- Insulation boards

- Switchgear

- Provide electrical safety

- Structural components

- Offer thermal insulation

- Insulators for spark plugs, heating elements, and furnace linings

These materials are found in residential, commercial, and industrial buildings

Automotive Industry

Examples of insulators in vehicles include, Such as:

- Electrical wiring

- Motor windings

- Gaskets

- Component insulation

- Thermal management in engine compartments and electrical systems.

Medical Devices

Insulating materials are essential in medical equipment, including:

- Imaging devices

- Monitoring systems

- Surgical instruments

They ensure electrical safety and proper functionality.

Aerospace and Aviation

Insulating materials are vital in:

- Aircraft and spacecraft electrical systems

- Ensuring safe operation

- Protection against electrical hazards

Testing and Standards for Electrical Insulation Materials

Testing and standards play a crucial role in ensuring the quality and reliability of these materials. Here are key aspects related to testing and standards:

Insulation Resistance Test

This test measures the electrical resistance of insulating material to prevent current leakage. It helps identify any defects or weaknesses in the insulation. This test ensures electrical safety.

Dielectric Strength Test

This test assesses the capacity to endure high voltage without experiencing a breakdown. It determines the most voltage without electrical breakdown to the insulating material.

Flame Resistance Test

This test evaluates insulating materials for resistance to ignition and flame spread. Moreover, this test determines performance in fire-related situations. This test is also essential for ensuring adherence to safety regulations.

Standards and Regulations

Standards and regulations govern the manufacturing and use of insulating materials globally. These standards establish performance criteria for insulating materials. Determine test methods to assess their properties. These standards also provide safety guidelines.

Safety guidelines to ensure quality and adherence to best practices in the industry. Adhering to these standards ensures consistent quality and promotes electrical safety.

Multiple international and national standards and regulations exist in this domain. Some notable ones include:

- IEC (International Electrotechnical Commission) Standards

- ASTM (American Society for Testing and Materials) Standards

- UL (Underwriters Laboratories) Standards

- NEMA (National Electrical Manufacturers Association) Standards

- RoHS (Restriction of Hazardous Substances) Directive

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) Regulation

- National Electrical Codes (NEC)

Compliance with these standards ensures insulating materials’ quality, safety, and reliability.

Future Trends and Challenges

The future of insulating materials holds several exciting trends and challenges. These trends aim to shape the field in the coming years. Here are three crucial areas to focus on:

Development of new insulating materials

Researchers are developing insulating materials with enhanced properties. The goal is to develop materials with enhanced electrical resistance and thermal conductivity. Another goal is to create materials with elevated mechanical strength and resistance to environmental factors. Nanotechnology and material science advancements enable novel materials with superior insulation capabilities.

These new materials may revolutionize industries with the contribution of enhanced performance and effectiveness. Such as electronics, power generation, and transportation.

Enhanced Performance and Miniaturization

As technology advances, there is a growing demand for insulating materials. That can support higher voltages and withstand extreme temperatures. This trend is particularly relevant in fields. Such as microelectronics, where components are becoming miniaturized. The challenge lies in developing materials that meet demands without compromising performance.

Environmental considerations

In an era of increasing environmental awareness. There is a strong focus on sustainable environmentally friendly insulating materials. The industry is seeking materials that are free from hazardous substances. These materials should be recyclable, biodegradable also. By reducing the environmental impact of insulating materials throughout their lifecycle. Industries can contribute to mitigating climate change and promoting a circular economy.

Summary of Electrically Insulating Material

In summary, these materials have diverse classifications. They have key properties for electrical safety and insulation. Moreover, they find applications in many industries. Future trends focus on developing materials with enhanced properties and performance. As well as future trends focus on environmental sustainability.