Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

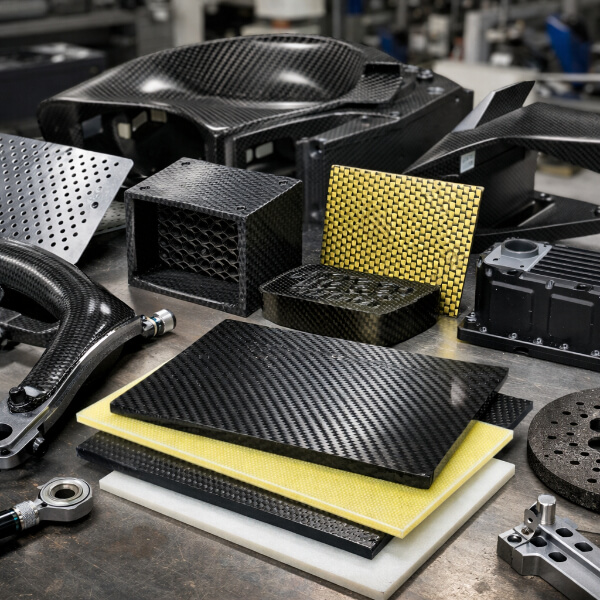

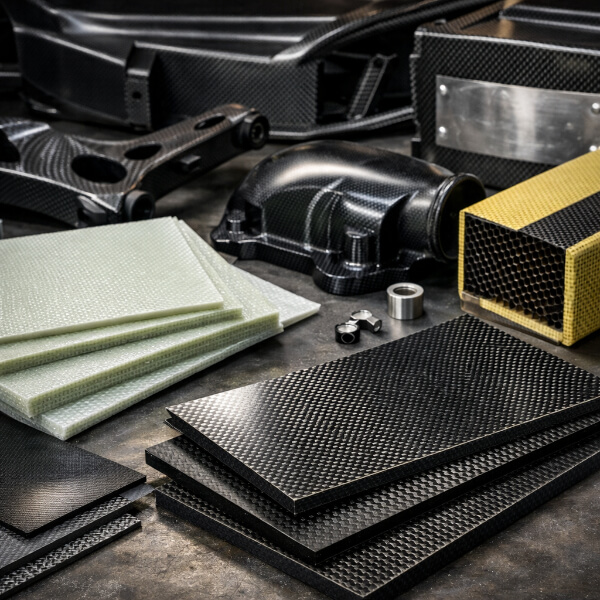

Composite materials are no longer an experimental option for high-performance vehicles — they are a design prerequisite. By combining engineered fibers and resin systems, modern composites let engineers tailor stiffness, weight, and crash behavior while enabling complex geometries that metal simply can’t achieve.

Composites provide a unique mix of properties that matter in racing and performance road cars:

Substantial mass reduction for equivalent structural capability, which improves acceleration, braking and handling.

Directional strength: fibers can be oriented to resist specific loads, optimizing stiffness where it’s needed most.

Design freedom: molded shapes and sandwich constructions enable aerodynamic integration and parts consolidation.

Resistance to corrosion and fatigue mechanisms that commonly affect metal components under cyclical loads.

When specifying a laminate, think in terms of fiber, matrix, and architecture:

Carbon fiber + epoxy: top choice when maximum stiffness and weight savings are the priority. Ideal for suspension elements, monocoque reinforcements and aerodynamic appendages.

Glass fiber systems: cost-effective, tougher in low-velocity impacts, and often used for panels and interior structural laminates.

Aramid (e.g., Kevlar) and hybrids: selected where controlled energy absorption and puncture resistance are needed, such as crash boxes and side-impact structures.

Specialty thermosets and fillers: used when flame retardancy, electrical insulation, or thermal shielding are required (battery trays, ECU enclosures).

Selection should be driven by the part’s mechanical targets, thermal environment, expected service life, repairability requirements, and cost envelope.

Different production methods suit different volumes and performance goals:

Prepreg layup and autoclave curing: delivers the most consistent mechanical performance and low void content — preferred for race-critical components.

Automated fiber placement (AFP): efficient for complex, high-accuracy laminates and medium-volume runs where repeatability matters.

Resin transfer molding (RTM) and compression molding: attractive for higher-volume or integrated-shape parts with reduced post-machining.

CNC finishing and abrasive cutting (waterjet): used to achieve mating surfaces, tolerances, and bolt patterns that allow parts to be assembled without additional fitting.

A pragmatic production strategy often combines methods — high-performance laminates are formed, then precisely machined to final geometry, ensuring both material integrity and assembly precision.

Good composite design anticipates manufacturing limits and end-of-life scenarios:

Design ply stacks around load paths rather than arbitrary symmetry.

Minimize concentrated fastener loads by using bonded inserts or load-distributing pads.

Define inspection-friendly features so non-destructive testing (NDT) can be applied easily.

Where repairability is expected, design to allow for section replacement and standardized repair procedures.

The result is a part that’s lighter and stiffer without introducing hidden failure modes.

Proven components require rigorous validation at material and assembly levels:

Mechanical profiling: tensile, compressive, shear, and fatigue tests that reflect real-world loading.

Environmental testing: thermal cycling, chemical exposure and humidity aging to mimic service conditions.

NDT methods: ultrasound, thermography and dye-penetrant techniques identify voids, delamination and manufacturing anomalies.

Traceability and batch control: resin and fiber lot records, cure logs and inspection results that support warranty, homologation, and failure analysis.

A formal quality system aligned with international standards (e.g., ISO 9001) reduces risk and accelerates component approval.

Composites are used wherever stiffness-to-mass, crash behavior or complex shapes matter:

Structural safety elements (bulkheads, cockpit reinforcements)

Aerodynamic components (splitters, wings, diffusers)

Load-bearing suspension parts and uprights

Battery trays and thermal shields for electrified performance platforms

Integrated interior structural laminates and mounting panels

Each application imposes a unique set of mechanical, thermal and regulatory constraints — matching material and process choices to those constraints is critical.

Write clear performance targets (mass, stiffness, life cycles) instead of vague requirements.

Request material certificates and cure data for each batch shipped.

Ask suppliers for inspection reports and recommended repair workflows.

Factor in machining tolerances and assembly interfaces when approving drawings.

Consider lifecycle costs — serviceability and spare-part provisioning often outweigh minor savings on initial price.

Specialist fabricators like Fenhar support racing and high-performance programs by combining tailored laminates with precision CNC finishing and waterjet cutting.

What makes a composite “high-performance” for automotive use?

A combination of advanced fibers, engineered resin systems, and controlled manufacturing that together deliver targeted stiffness, low mass and predictable failure modes.

Are composite parts repairable after crash damage?

Yes — many parts can be repaired using standardized methods, but repairability depends on the laminate architecture and service requirements.

How do I ensure a composite part meets safety standards?

Specify required tests (static, fatigue, environmental) up front and require material traceability and NDT reports from your supplier.

What manufacturing method gives the best mechanical properties?

Prepreg layup cured under controlled temperature and pressure (typically in an autoclave) produces very consistent properties.

Do composites save lifecycle energy compared to metal?

Often — lightweight components reduce operational energy use, though lifecycle assessments depend on manufacturing processes and end-of-life handling.