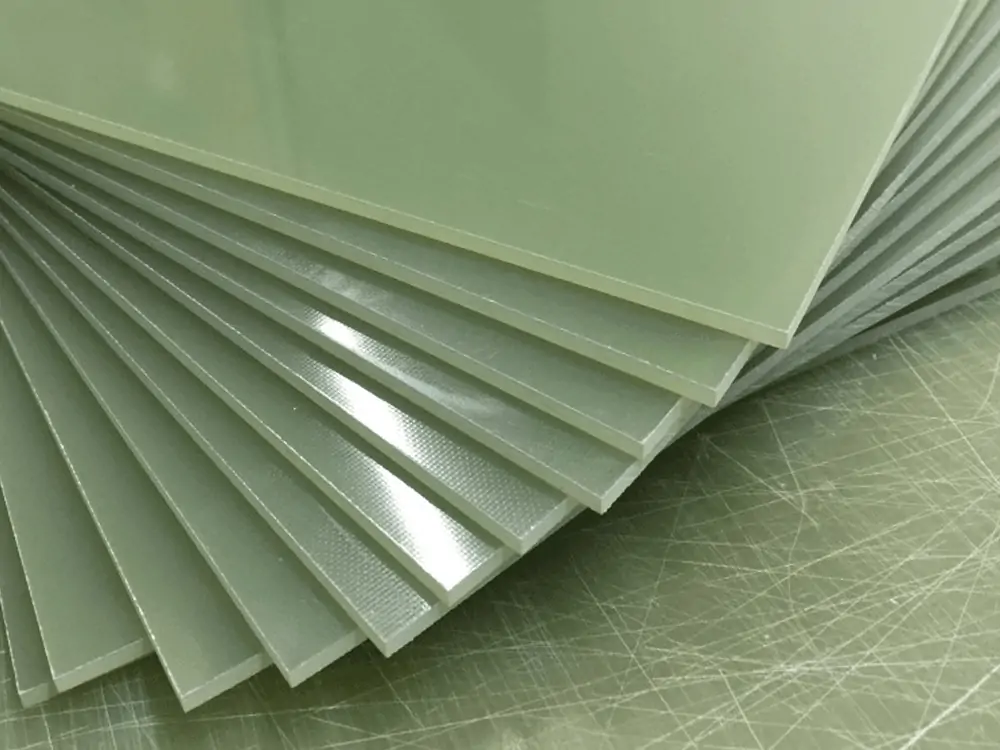

Garolite is also known as G-10. Composite material materials have many types like G-10. It can endure high pressure. We can form it by assembling many films of glass cloth. Then we saturate sheets of glass in epoxy resin. These films and epoxy resins are then compressed to a resulting material under heat. Manufacturers produce this material in the form of bulk and convert them into sheets. The thickness of these sheets ranges in millimeters.

G-10 is quite like carbon fiber coats. G-10 is also like Micarta. Glass cloth, has different uses. We can use it as a filler material. In glass fiber epoxy laminates G-10 is the hard one. Thus, we can use them in our routine life.

Properties of g10 fr4 glass epoxy

Some properties of G-10 are

- It has high strength

- It has low moisture absorption

- It has high electrical insulation

- It has a good chemical resistance level

We can have these properties at room temperature. These properties are upheld under damp or saturated conditions. In ancient times it was first used as a substance for reproduced circuit boards. We can use them for naming the material. “National Electrical Manufacturers Association standard” talks about material manufacturing like G-10.

Uses of G10 FR4

- We can use G-10 to produce Decorative variations in different colors and patterns. They are especially used to make handles for scissors and knives, clutches for weapons, and other utensils. Solid grip and proper hold are due to the texture of that material. We can carve or texture them, i.e., blob blasted, sandpapered, or scraped. It has higher strength. Its low density allows it to be useful. It is used in different varieties of handcrafting.

- G-10 is a reinforcement for ends of fiberglass-covered wood. The manufacturer used it to protect the abrasion. It smoothens the point of contact between such things. Generally, G-10 is an important material that absorbs the effects of shock. In such uses and applications, you should replace it as it deforms and tears.

Hazards

G-10 is used for managing extreme conditions.

A lot of problems result from cutting and crushing the material. Glass and epoxy powder or dust contributes to lung infections. They enhance the risk of lung cancer. To protect ourselves from these disorders, the workstation must be aired. One should wear a mask and glasses for protection from epoxy dust and flames.

Epoxy resin can catch flame. Once kindled, it will burn. It releases poisonous and hazardous gases. These flames can cause serious health problems like cancer.

G-10 FR-4 Material Formation

G-10 FR-4 is known as “Thermosetting industrial fiberglass composite laminate”.

It consists of an unremitting filament glass cloth. Besides it also consists of a material with a binder called epoxy resin. People found it in the 1950s. It has different major physical characteristics as well as chemical properties such as good strength. These materials absorb low moisture. They have brilliant electrical properties.

What’s more, they also have exceptional chemical resistance. We can maintain some of its properties at room temperature. National Electrical Manufacture Association (NEMA) gave the name of this material “NEMA G10”.

The name of the Westinghouse trade was Micarta. Micarta sheets are one of the most famous products of their company. There are many Micarta materials that can be any of the many NEMA Manufacturing laminate scores. Some Micarta materials are specific to be G-10.

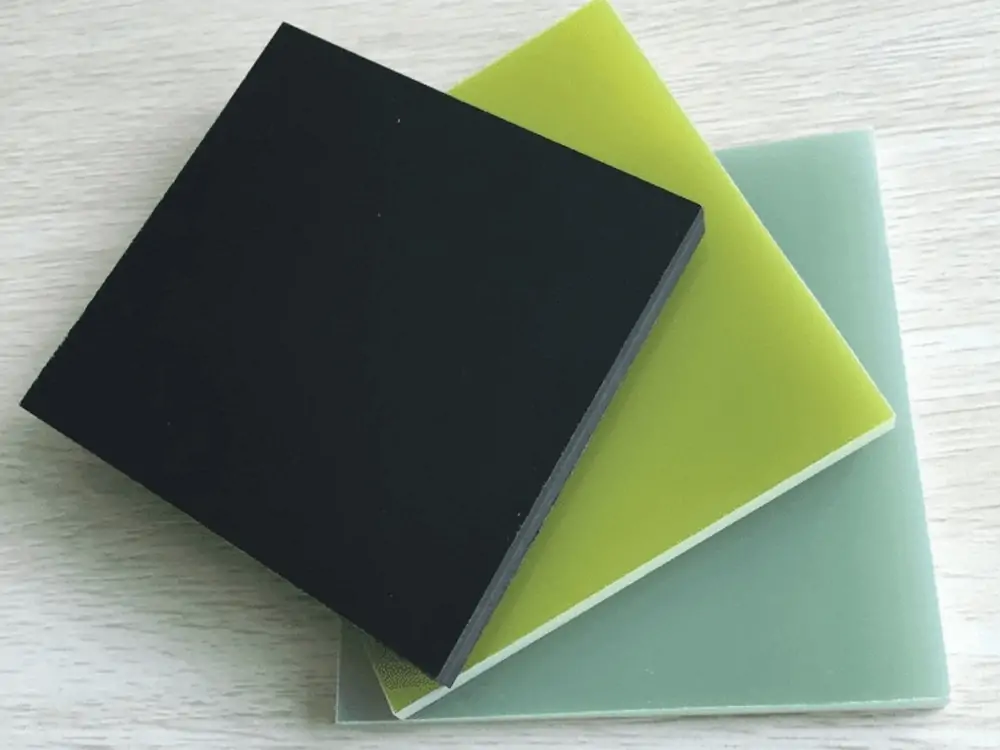

Base materials are epoxy resin and fiberglass. The color of materials can be changed according to the requirements and will of the customer. It may be of different colors like yellow, black, and green.

Applications

It is a multifunctional epoxy. It makes up a huge mass of hefty sheets. We use bigger glass cloth. It has high-temperature resistance. There are tetra-functional epoxy sheets that give a high-performance external texture.

Today the material called G10 composite is an FR4 material. G-10 FR-4 is the Brominated flame-retardant material. We must use G10 laminated with FR-4 material. In this way, we can build different materials.

Manufacturers use a unique variation of the G10 fiberglass sheet called G10 CR laminate in cryogenic applications.

285-degree F is a continuous operating temperature for G10 FR-4 materials. These materials are thermosets. There is no melting occurring with this temperature.

We observe carbonizing after prolonged areas above this temperature range. FR-4 materials have an Underwriter’s Laboratories (UL) flammability rating of 94 V-0.

G10 Tube

We can stock G-10 Tubes at (PPC) Polymer Plastics composites to restricted extents. Factory can usually make it to order. Workers can use this process in the same epoxy-saturated glass cloth. Then they assemble the material component into sheets. Next, they can coil them over arbors. Finally, we crush them and grind them to a specific size.

G10 FR4 Rod

And our factory can turn G-10 FR-4 material into Rod too. We can grind them from sheet stock. We can make a special order according to our choice. They must Mil-Spec grade trundle and shape the rod based on custom order.

Conclusion:

Epoxy fiberglass is an industrial product used everywhere. Its performance in buildings is admirable. In marketable buildings, it has great use. It has the ability to repel chemicals. We can clean it with simple water. There is a well-known use of epoxy resins in decoration. Some decoration pieces are used due to their beauty and aesthetic charm. Their glassy look is used in the flooring of houses and buildings. They are beautiful and aesthetic in any area in any setting. Professional workers can install all the major products quite well. It is useful as a matter of taste and personal preference. Professional workers and manufacturers like it.