Phenolic paper is a versatile composite material with diverse industrial applications. This article aims to provide a thorough understanding of its properties and uses.

Definition of Phenolic Paper

It is a type of laminate that is produced by saturating paper with phenolic resin. The resin-infused paper is then subjected to high pressure and temperature. Then results in a rigid, durable, and heat-resistant material.

This article explains phenolic paper and its applications comprehensively. It explores its properties and importance in various industries. It is used in electrical insulation, gaskets, and chemical processing. Understanding its capabilities inspires innovative solutions in different sectors.

Properties and Characteristics of Phenolic Resin

Phenolic resins possess excellent properties for various applications, including high heat resistance. They can withstand temperatures from -40°C to 150°C.

Additionally, phenolic resin sheets have excellent mechanical strength, electrical insulation, and chemical resistance. It is ideal for demanding environments.

The Composition and Manufacturing Process of Phenolic Paper

Phenolic resin is a synthetic polymer made by reacting phenol and formaldehyde. It finds extensive use in producing composite materials, including phenolic paper or phenolic laminate.

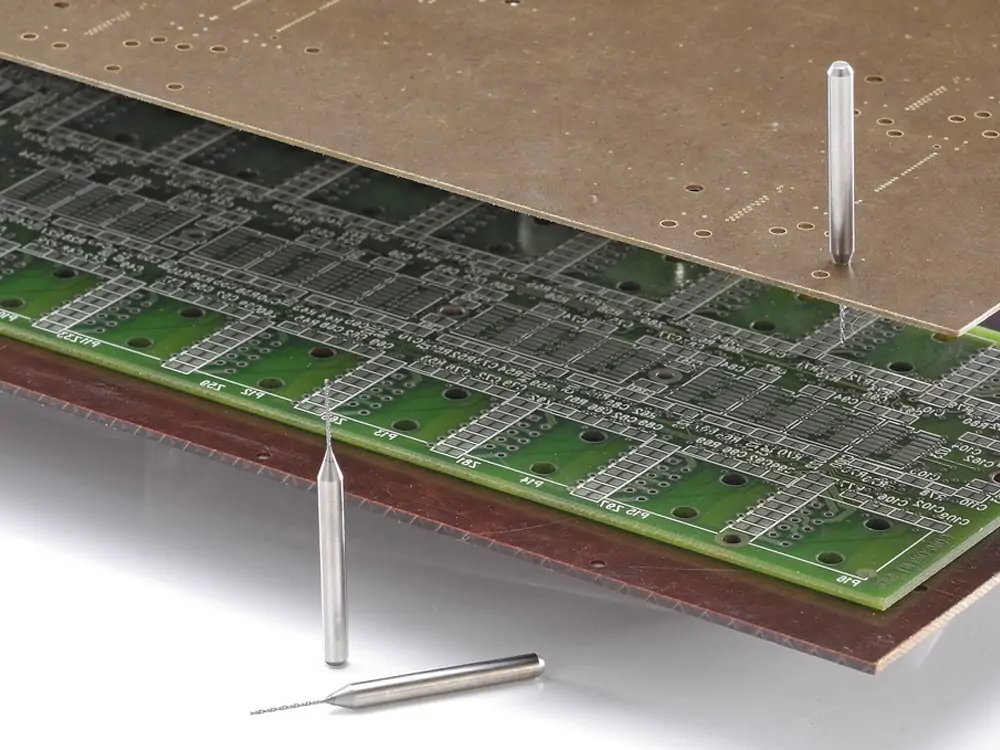

How Phenolic Paper is Made

Its manufacturing process involves several key steps:

- Selection of Paper Materials:To create phenolic paper, select the high-quality paper with controlled thickness and density. Choose paper that is free from impurities and has good mechanical strength.

- Impregnation with Phenolic Resin: The paper is soaked in a phenolic resin bath and subjected to vacuum and pressure. This process fully saturates the paper fibers with resin. This process strengthens the paper and enhances its resistance to heat and chemicals.

- Curing Process: The resin-impregnated paper undergoes heat and pressure, which cures the resin. This process creates a strong and durable composite material by bonding the paper layers together.

Variations in Manufacturing Techniques and Resulting Product Properties

Manufacturers employ various techniques to produce phenolic paper with specific properties. They adjust factors like resin type, concentration, and curing conditions. These adjustments enhance flame retardancy and improve electrical insulation properties.

Properties and Characteristics of Phenolic Paper

This material is widely recognized for its extraordinary characteristics.

These unique attributes make it highly sought-after in numerous industries. Let’s explore some of its key characteristics.

Mechanical Strength and Durability

- It exhibits remarkable mechanical strength. This property makes it capable of withstanding high levels of stress and pressure.

- It has excellent tensile strength and dimensional stability. This property ensures its durability even in demanding applications.

- Also, this property makes it suitable for components that require structural integrity. Such as bearings, gears, and structural reinforcements.

Flame Resistance and Fire Retardancy

One of the most noteworthy edges of it is its premium flame resistance and fire retardancy. This substance possesses a high ignition temperature and does not readily support combustion. When this material is subjected to fire, it develops a defensive layer of char. This char layer acts as a barrier and prevents the spread of flames. This characteristic makes it an excellent option for materials that are resistant to fire. Including electrical enclosures, circuit boards, and aerospace applications.

Electrical Insulation Properties

This material has excellent electrical insulation properties. It possesses excellent dielectric strength and a low dissipation aspect. In addition, it can isolate electrical components and block the passage of current.

This characteristic renders it appropriate for use in electrical insulation applications. It is utilized in materials requiring insulation to guarantee secure and dependable functioning. Such as circuit breakers, transformers, motors, and other electrical machines.

Chemical Resistance

- It exhibits remarkable resistance to various chemicals.

- It has also resistance to acids, bases, solvents, and oils.

- It remains stable and unaffected by corrosive substances.

This characteristic makes it well-suited for applications that involve exposure to chemicals. It is frequently utilized in equipment for chemical processing, pipe fittings, and storage tanks. This is because the ability to withstand chemical corrosion is crucial in this equipment.

Thermal Stability

It offers excellent thermal stability. This remarkable feature allows it to endure high temperatures without experiencing substantial deterioration. Even under extreme heat conditions, it maintains its mechanical properties and dimensional stability.

Its thermal insulation properties make it ideal for heat shields and barriers. Such as in automotive parts, ovens, and industrial machinery

Applications of Phenolic Paper

It has exceptional properties and is used in many industries. Let’s examine some of its primary uses across various industries.

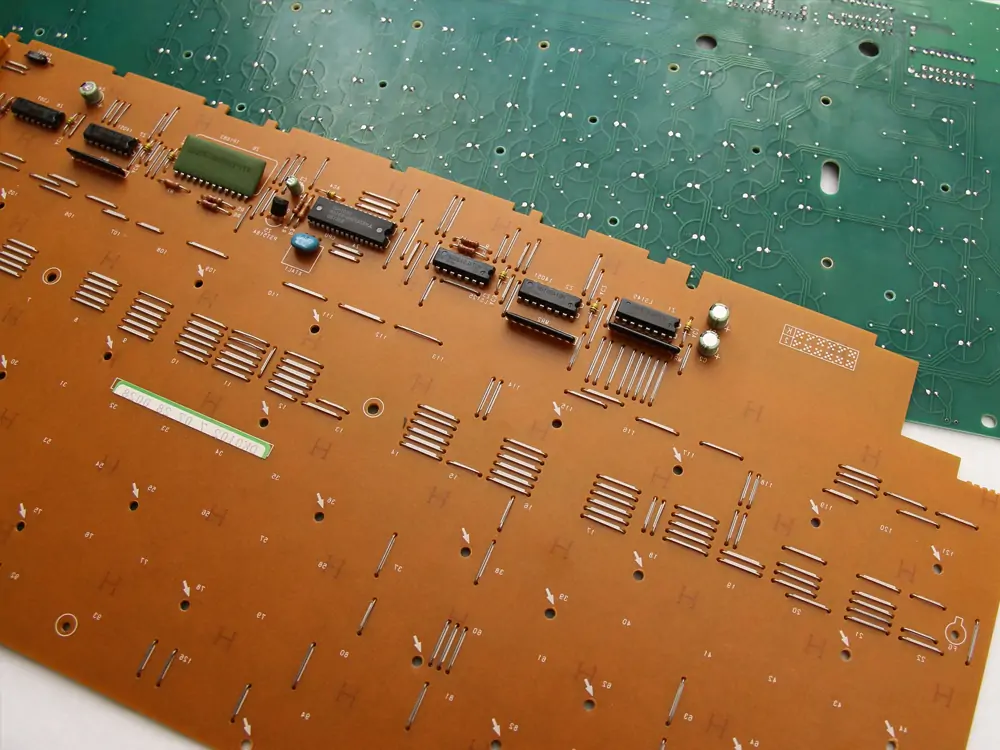

Electrical Industry

The electrical industry extensively utilizes it due to its excellent insulating properties.

It is commonly used in transformers and electric motors. It aids to prevent electrical conductivity and ensures safe and efficient operation. Printed circuit boards (PCBs) and electrical laminates are also made of it. It equips a strong and reliable base for electronic devices.

Automotive Industry

In the automotive industry, phenolic paper plays a vital role in brake and clutch linings. Its heat resistance and low friction coefficient make it perfect for critical components. Its durability ensures reliable and efficient braking systems. Gaskets and seals are commonly manufactured using this material. It effectively seals and prevents fluid leaks in automotive systems.

Construction Industry

It finds multiple applications in the construction sector as well. It is a commonly utilized material in buildings for thermal and acoustic insulation. This insulation plays a crucial role in energy efficiency and soundproofing. Its excellent thermal resistance helps regulate indoor temperatures. It also ensures comfort while lowering energy usage. It improves surfaces like countertops, furniture, and wall panels with decorative laminates.

Other Industries

The paper phenolic has diverse applications, extending beyond the previously mentioned industries. The aerospace industry employs it for lightweight, strong, and fire-resistant components.

In marine and shipbuilding, it insulates pipes and equipment. Its insulation safeguards them against heat and fire.

Advantages and Limitations of Phenolic Paper

Advantages

It has numerous advantages, making it favorable in diverse industries.

Cost-effectiveness:

The phenolic paper offers a notable benefit in terms of being cost-effective. Compared to other high-performance materials, it is fairly affordable. Its low cost makes it an appealing choice for projects on a tight budget.

Versatility and wide range of applications:

Phenolic paper is versatile and finds use in various applications. It is commonly employed in electrical insulation, like circuit boards and transformers. Because of its strong durability and ability to withstand damage, it is widely used in different industrial components. Such as automotive parts, aerospace components, bearings, and gaskets.

Excellent performance in harsh conditions:

It excels in demanding environments. It demonstrates exceptional resistance to high temperatures. This is ideal for situations requiring the utmost thermal stability. Moreover, its excellent resistance to chemicals ensures its reliability in corrosive environments.

Limitations

The phenolic paper has limitations despite its advantages, which should be considered.

Limited color options and aesthetic appeal:

- The usual color options for this item are limited to brown and black. These limited color options may not meet specific aesthetic requirements or visual appeals.

- It is important to note that phenolic paper prioritizes functional properties over appearance. This material is not suitable for applications that require strong dimensional stability.

Vulnerability to moisture:

One of the limitations of it is its vulnerability to moisture. Prolonged or excessive moisture can cause it to absorb water. This leads to swelling, warping, and reduced mechanical properties.

When utilizing it in moist or damp conditions. It is crucial to ensure its proper sealing and protection. Exposure to strong acids or alkalis can affect its chemical resistance.

Comparison between phenolic paper and other materials

Phenolic paper possesses unique properties that set it apart from other materials.

Phenolic Paper vs. Phenolic Cotton

These are both laminates made with phenolic resins. However, they have contrasting base materials. The phenolic paper uses paper as the substrate, while phenolic cotton uses cotton fabric. The phenolic paper provides higher mechanical strength and dimensional stability than phenolic cotton. It has enhanced moisture resistance, making it ideal for humid conditions.

Phenolic Paper vs. Glass Epoxy

FR4, also known as glass epoxy, is a type of laminate composed of woven glass fabric combined with epoxy resin. Both materials provide electrical insulation. But phenolic paper excels in heat resistance. Therefore, it outperforms glass epoxy in maintaining mechanical integrity at high temperatures.

Phenolic Paper vs. Other Insulation Materials (e.g., Fiberglass, Polyester)

Phenolic paper surpasses fiberglass and polyester insulation materials with its superior heat resistance. Fiberglass is strong and chemical-resistant but may falter under high temperatures. Polyester, though flexible and cost-effective, lacks the heat resistance of phenolic paper. This makes the phenolic paper a trustworthy option for demanding applications in diverse industries.

Safety Considerations and Environmental Impact

Handling and Safety Precautions

When working with phenolic paper, follow these safety precautions for proper handling:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, safety glasses, and protective clothing. This approach reduces the chance of skin contact and prevents potential eye injuries.

- Ventilation: Ensure proper ventilation to prevent harmful fumes from accumulating in the work area.

- Dust Control: Use dust collection systems and wear respiratory protection to minimize dust particles.

- Fire Safety: It can easily catch fire, particularly when it comes into contact with extreme heat or an open fire. Keep the material away from ignition sources. Use fire-resistant storage and handling procedures.

- Storage and Transportation: Store it in a dry, well-ventilated area. Keep it away from heat, direct sunlight, and incompatible materials. Follow proper handling procedures during transportation to prevent damage and accidents.

Environmental Sustainability and Recycling Options

It has certain environmental considerations, and sustainable practices should be encouraged. Here are some crucial aspects to consider:

- Recycling: It can be recycled through various methods. The paper layers can be separated from the resin and recycled as paper waste. The resin can be thermally decomposed and used for energy recovery.

- Waste Management: Properly manage waste to prevent environmental pollution by following local regulations and guidelines. Dispose of unused or wasted phenolic paper accordingly.

- Green Alternatives: Promote eco-friendly alternatives to phenolic paper, like bio-based laminates or recycled composites. These alternatives reduce the environmental impact.

- Life Cycle Assessment: Conducting a life cycle assessment of phenolic paper helps identify areas for improvement. It assesses energy consumption, waste generation, and overall environmental impact. The assessment guides the development of sustainable practices and materials.

Encouragement for Further Exploration and Application of Phenolic Paper

It offers remarkable properties, motivating exploration and application in diverse fields. It resists heat, and chemicals, and lasts long, providing numerous opportunities for innovation. The electrical industry can benefit from it in circuit boards, insulators, and transformers. In automotive, it can replace heavier materials, improving performance and fuel efficiency. The aerospace sector can use it in interiors, engines, and insulation systems for extreme conditions. By encouraging further exploration, we can unlock its full potential and drive innovation. Its exceptional properties make it valuable for future advancements in multiple industries.