Introduction of Aramid paper

Aramid paper is a specialized material crafted from synthetic fibers. Meta-aramid and para-aramid are the names of these fibers. Their exceptional strength and heat resistance have made these materials famous.

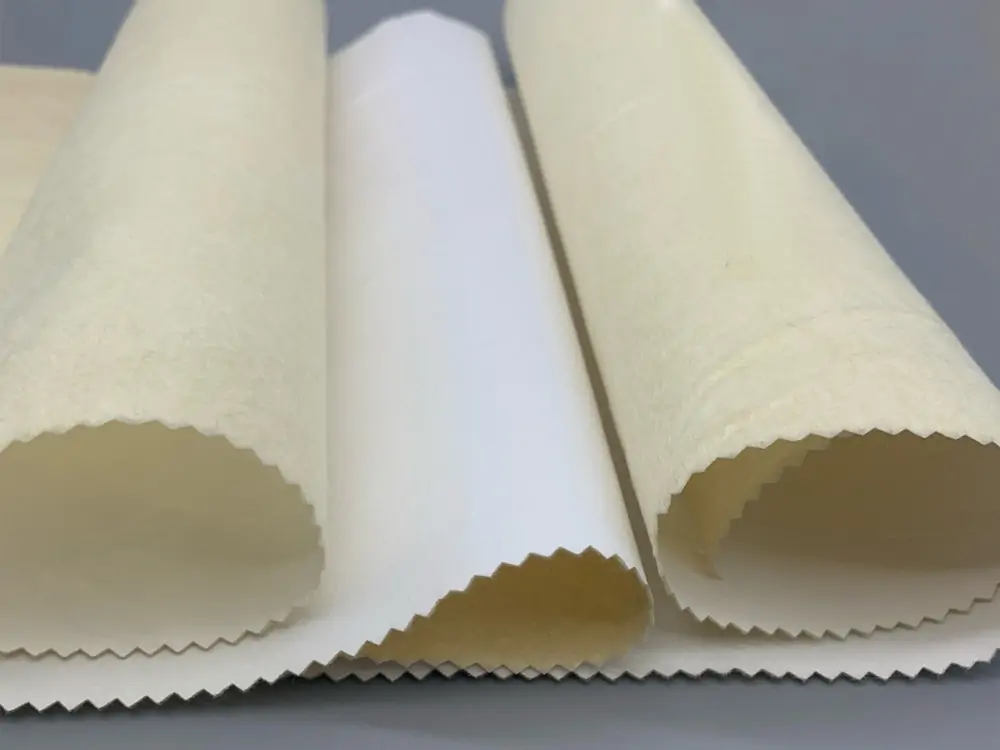

Definition

Aramid paper is a strong and heat-resistant material. Synthetic polymers and aramids make up its composition, offering remarkable toughness and resistance. Long-chain molecules form a compact and dense structure. Industries widely utilize this paper type due to its distinct attributes.

Development and Discovery

Aramid paper’s journey began in the 1960s with scientist Stephanie Kwolek’s breakthrough at DuPont. Kwolek’s research resulted in the development of Kevlar. Kevlar was the first aramid fiber while experimenting with polymers. This discovery paved the way for its development.

The breakthrough’s impact touched on diverse fields from aerospace to automotive and beyond. Its strength-to-weight ratio was impressive. This quality made it great for reinforcing materials without making them bulky.

Importance of Aramid Paper

It plays a crucial role in enhancing safety across industries. Let’s discuss some of its industrial importance.

- In aerospace, it strengthens aircraft components, reducing potential failure points.

- In automotive engineering, it’s used in brake pads. Because it endures high temperatures and ensures reliable performance.

- This paper’s flame resistance is pivotal in firefighter gear. Furthermore, it provides a protective barrier against extreme heat.

- Additionally, it has use in bulletproof vests and helmets. As it enhances personal protection for law enforcement and military personnel.

- In the electronics realm, it acts as insulation in power cables due to its non-conductive properties. Evidently, this prevents electrical hazards and ensures stable power transmission.

Composition and Structure of Aramid Paper

It is a remarkable material known for its exceptional strength and heat resistance. It undergoes a meticulous manufacturing process. This process involves three steps.

Preparing the Raw Materials

Aramid paper production begins with sourcing two primary raw materials. These raw materials are an aromatic amine and an aromatic acid chloride. These ingredients, derived from petrochemicals, serve as the foundation for the aramid polymer.

The aromatic amine and acid chloride are mixed in specific ratios to form a monomer solution. This solution undergoes a reaction, known as the Friedel-Crafts acylation. This reaction creates the aramid polymer. The reaction is closely managed to meet the intended molecular weight and properties of the polymer.

Polymerization and Spinning of Aramid Fibers

Aramid polymer goes through polymerization. In this process, monomers chemically bond to create long chains. The outcome is a strong and rigid polymer. The polymer is then dissolved in a solvent to create a liquid solution.

The technique of wet spinning involves extruding the aramid solution through fine nozzles. The fine nozzles release the aramid solution into a coagulation bath. This bath causes the polymer chains to solidify into fibers. The fibers are then washed, stretched, and wound onto bobbins. These aramid fibers boast extraordinary tensile strength and heat resistance.

Formation of Aramid Paper Sheets

By mixing aramid fibers with water and a binder solution a fiber dispersion formed. Pour the fiber dispersion onto a forming screen. Allow water to drain away from the dispersion. Leave behind a uniform mat of aramid fibers on the forming screen. Put pressure on the fiber mat to get rid of excess water and make sure fibers adhere correctly. The mat is then dried and finally called aramid paper sheets.

Characteristics of Aramid Paper

It exhibits exceptional properties in various industries due to its unique material composition. Let’s delve into the key attributes that make it stand out.

High Tensile Strength and Its Significance

It boasts immense tensile strength, resisting stretching and enduring heavy loads. This strength is pivotal for applications demanding durability, like aerospace and bulletproof vests.

Exceptional Heat Resistance and Thermal Stability

With remarkable heat resistance, aramid paper maintains its integrity at elevated temperatures. Industries such as automotive and electronics benefit from this ability to withstand heat stress.

Low Weight and Excellent Mechanical Properties

This paper offers remarkable mechanical properties. It suits well for creating lightweight and strong solutions. This makes it perfect for applications in sports equipment and structural components.

Electrical Insulation Properties

Its superb electrical insulation properties make it indispensable in electrical systems. Its non-conductive nature ensures safety and reliability in insulation applications.

Chemical Resistance

Its resistance to various chemicals is a vital characteristic in harsh environments. It flourishes when exposed to substances that could deteriorate other materials. It is valuable in chemical processing and industrial situations.

Applications of Aramid Paper

This paper has diverse uses in various industries due to its amazing properties. Its contributions span from improving safety to enhancing performance, creating a versatile material. Let’s explore its remarkable applications.

Electrical Industry

It finds vital roles in the electrical sector as it has exceptional insulating properties. This paper shields wires and cables from electric currents, enhancing safety and performance. In addition, Its lightweight and durable nature makes it a perfect option for insulating transformers.

Aerospace and Defense

In aerospace, it shines as a reinforcement material in composites. It ensures lightweight yet strong structures for aircraft and spacecraft. Its flame resistance and thermal stability make it valuable for military applications.

Automotive Industry

Its heat resistance and mechanical strength benefit the automotive sector. It’s used in gaskets, brake pads, and clutch plates. Besides, its lightweight nature aids in fuel efficiency and performance.

Filtration

Moreover, its fine fibers are superb for filtration purposes. It’s employed in air and liquid filters, capturing particles effectively. Its stability under varying conditions ensures lasting filtration performance.

Construction and Engineering

Another key point is that this paper reinforces construction materials like concrete and adds strength to structures. It’s used in seismic retrofitting and repairing of historic buildings. Its non-corrosive nature extends the life of infrastructure.

Sports and Recreational Equipment

It also brings durability to sports gear. Skiing, cycling, and even musical instruments benefit. It’s impact resistance and lightweight properties elevate safety and performance.

Advantages and Limitations of Aramid Paper

It possesses numerous benefits and some limitations. Its exceptional properties suit diverse applications. However, recognizing its drawbacks is vital for informed choices.

Advantages

- The lightweight quality of this paper doesn’t compromise its strength. Industries that need durability and reduced weight seek this material.

- It has natural flame-resistant qualities. It is highly valuable in places with high temperatures and fire risks. It offers protection in such environments.

- This paper also resists chemicals and electricity effectively. This quality enhances its versatility in various applications. It serves as electrical insulation and protective gear in hazardous settings.

Limitations

- Its advanced manufacturing processes raise its cost compared to conventional materials. These processes affect the economic viability of certain projects.

- Additionally, it can absorb water easily, which affects its mechanical and electrical characteristics. This makes it unsuitable for damp environments.

Comparison with Other Materials

Aramid Paper vs. Traditional Paper

A high-performance material is Aramid paper which differs significantly from traditional paper. Aramid paper is crafted from aramid fibers, while traditional paper uses wood pulp. Aramid paper impresses with its incredible strength, ability to withstand heat, and durability. Traditional paper, being weaker, is more susceptible to tearing and damage.

Aramid Paper vs. Carbon Fiber

Both materials exhibit contrasting characteristics. Aramid paper is flexible, lightweight, and electrically insulating. Carbon fiber, rigid and lightweight, offers high strength and conductivity. Aramid paper emphasizes flexibility while carbon fiber prioritizes strength.

Aramid Paper vs. Aramid Fabrics

Both materials share aramid fibers but serve different purposes. Aramid paper is a sheet-like material with electrical insulating properties. While aramid fabrics, woven or non-woven, offer exceptional strength and impact resistance. Aramid paper focuses on insulation while aramid fabrics prioritize strength and protection.

Future Trends and Developments

In the realm of aramid paper technology, exciting advancements are on the horizon. Research and innovation are steering this evolution, promising enhanced properties and applications.

Research and Innovation in Aramid Paper Technology

Researchers are fervently exploring novel avenues to bolster its performance. Enhanced durability, fire resistance, and electrical insulation are focal points. Cutting-edge techniques like nanotechnology and advanced polymer blending hold promise.

Innovations span manufacturing processes, striving for eco-friendliness and scalability. Sustainable sourcing of aramid fibers and energy-efficient paper production are areas of intense focus.

Collaboration between academia and industry drives breakthroughs, expediting technology transfer. This synergy facilitates quicker adoption of new aramid paper advancements.

Emerging Applications

Beyond traditional applications, this paper is finding new roles in diverse sectors. Automotive industry adoption is increasing due to its lightweight strength and crash-resistant potential.

- It is integrated into wind turbine blades for increased strength in renewable energy. This enhances the structural integrity of the blades. Its electrical insulation prowess benefits high-power electrical systems.

- In medical fields, it is being used in advanced wound dressings. As it provides flexibility and antimicrobial abilities.

- Designers are exploring this paper in textiles to blend style and durability in the fashion world.

- Moreover, architecture exploits this remarkable paper for earthquake-resistant structures and innovative interior design.

- Space exploration benefits from its lightweight versatility in satellite components.

- Advancements are poised to revolutionize various sectors in the upcoming years. These changes could greatly impact packaging, wearables, and robotics.