Introduction

Mica tape is an extraordinary material widely used in various industrial applications. In this article, we will delve into the world of Mica tape by exploring its unique properties and its manufacturing process.

Definition and Overview

Mica tape is a specific kind of tape manufactured using Phlogopite or Muscovite mica. It is combined with a suitable binding material. This combination results in a flexible, heat-resistant, and electrically insulating tape.

Historical Backdrop

The roots of Mica tape trace back to ancient times. Civilizations discovered Mica’s unique properties for cave painting protection. It was used in ancient Egyptian artifacts for various purposes.

However, In the 19th and 20th centuries, Mica tape entered modern industries. This happened because of its exceptional thermal and electrical insulation abilities.

Types of Mica Used in Mica Tape

There are two primary types of Mica, Phlogopite, and Muscovite, used in the production of Mica tape. Phlogopite Mica is renowned for its outstanding resistance to high temperatures. On the other hand, Muscovite Mica offers excellent electrical insulation properties.

Properties of Mica Tape: A Marvelous Compilation of Features

It is renowned for its incredible versatility. It boasts many remarkable properties that set it apart from conventional materials. Let’s take a concise journey through its outstanding attributes:

Thermal Resistance and Heat Dissipation:

It possesses exceptional thermal resistance, safeguarding equipment from high temperatures. Its ability to dissipate heat efficiently ensures optimal performance and longevity. This distinctive characteristic renders it a perfect option for challenging applications.

Electrical Insulation:

As an effective insulator, it prevents electrical currents from leaking. It ensures safety and prevents potential hazards. Its reliable insulation capabilities make it a prized component in various electrical systems.

Flame Resistance:

Its impressive flame resistance makes it a vital asset in fire-prone environments. By impeding the spread of flames, it acts as a valuable shield. Thus, it protects both equipment and personnel from flame.

Mechanical Strength:

Despite its lightweight nature, it boasts remarkable mechanical strength. It can withstand challenging conditions, including vibrations and mechanical stress. This character makes it a reliable and durable material.

Chemical Stability:

It exhibits excellent chemical stability. It exhibits remarkable resistance to corrosion and degradation caused by diverse chemicals. This attribute ensures the tape’s longevity and reliability in harsh chemical environments.

Flexibility and Tear Resistance:

Its inherent flexibility allows easy conformation to shapes and contours. This property makes it ideal for intricate applications. Moreover, its tear resistance ensures that it remains intact under demanding conditions.

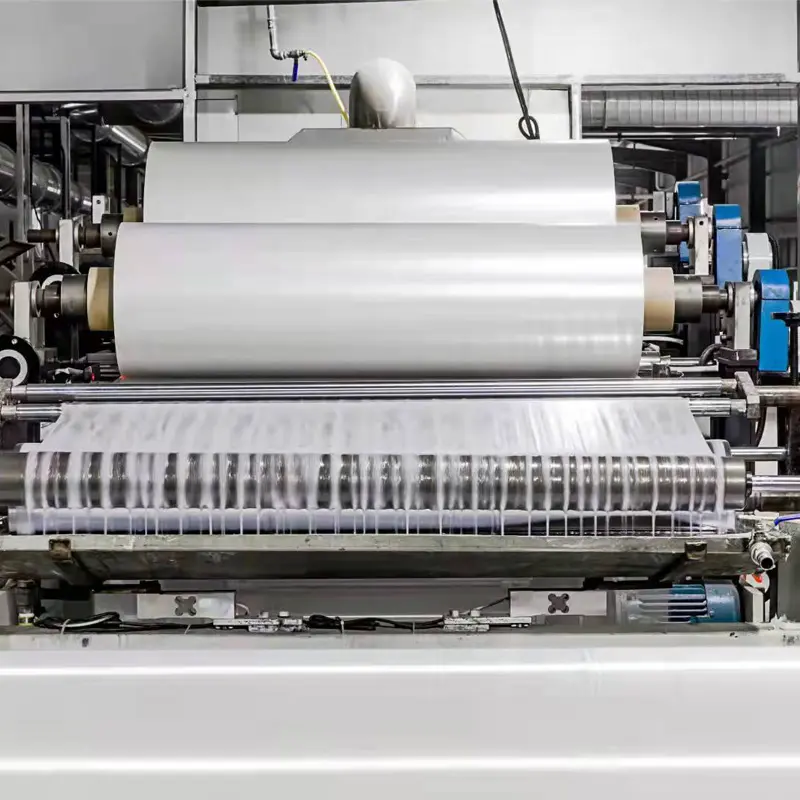

Manufacturing Process of Mica Tape

It is a versatile and essential material in various industries. It goes through a rigorous manufacturing process to guarantee its extraordinary characteristics. Here’s a simplified overview of the step-by-step journey from raw materials to the final product.

- Sourcing and Preparation of Mica:

The process starts with sourcing premium mica flakes, a naturally occurring mineral. Mica boasts amazing thermal and electrical insulation characteristics. After selecting the finest mica, it undergoes thorough cleaning and processing. This step removes impurities, guaranteeing a pure and reliable tape base. - Bonding Agents and Reinforcement Materials:

Bonding agents and reinforcement materials are essential for its production. They hold mica flakes together and add extra strength to the tape. A careful mixing process of them creates a uniform and cohesive mixture. This mixture is then combined with the mica for integration. - Layering and Lamination Techniques:

The manufacturing process centers on layering mica with a bonding agent mixture. Precise lamination techniques ensure an even distribution of materials. They create a robust and uniform tape structure. The mica and bonding agent mixture are layered one on top of another. Careful application of each layer builds the desired thickness and strength. - Drying and Curing Process:

After the layers are assembled, it goes through a vital drying and curing stage. This process is essential to eliminate any residual moisture. This process also allows the bonding agents to set and solidify. Controlled temperatures and conditions ensure the tape’s stability and reliability.

Applications of Mica Tape

Its exceptional properties find diverse applications in various industries. Let’s explore some of the key uses of this magical material:

Electrical and Power Cables

It is crucial for electrical and power cables worldwide.

Its excellent electrical insulation ensures cable safety and performance. Also, It withstands high temperatures, making it ideal for power networks.

Fire-resistant Cables

It is a fire safety superhero, adding protection to cables.

It prevents fires and minimizes flame spread in mishaps.

Critical infrastructures and buildings rely on it for enhanced safety.

Motors and Transformers

It shines in motors and transformers, boasting thermal stability and electrical insulation. It becomes indispensable and enables the efficient and durable operation of these devices.

Insulation for High-Temperature Appliances

Mica Tape steps up for high-temperature appliances, offering top-notch insulation. It contains heat, improving performance, from hair dryers to toasters. Industrial ovens benefit too, as it prevents damage and enhances efficiency.

Automotive Industry and Aerospace Sector

It insulates automotive components and aircraft systems. It ensures reliability and prevents electrical issues. It protects wiring systems and reduces the risk of malfunctions in vehicles.

Oil and Gas

It insulates cables and controls systems in the oil and gas industry. It works in high-pressure, high-temperature environments.

Renewable Energy

It enables reliable and safe operation in renewable energy applications. It offers both electrical insulation and fire resistance for solar panels and wind turbines.

Advantages and Limitations of Mica Tape

It is a versatile material widely used in insulating materials due to its unique properties. Let’s explore its advantages and limitations.

Advantages:

- It excels in extreme temperatures for crucial insulation in high-heat environments.

- Its outstanding dielectric properties lower the likelihood of short circuits and electrical failures.

- Additionally, it is inherently flame retardant, adding safety in fire hazard situations.

- It is a flexible material that applies to irregular shapes on diverse surfaces.

- It is resistant to chemicals that safeguard sensitive equipment and components.

- It emits low smoke levels during fires that reduce harm to individuals and equipment.

Limitations and Challenges:

- Complex production procedures contribute to relatively higher costs.

- It possesses brittleness and susceptibility to cracking under mechanical stress.

- Excessive moisture exposure can impact insulation properties, requiring careful handling.

- Sourcing high-quality mica is challenging due to limited availability, affecting production volumes.

- Specialized adhesives and techniques may be needed for proper bonding.

- Mica mining and processing have environmental impacts. Therefore, sustainable sourcing and recycling are crucial to mitigate the environmental impacts.

Comparison with Other Insulation Materials

Mica Tape vs. PVC Tape

They both differ in electrical insulation properties due to their origins. Mica Tape, from natural mica, excels in heat resistance and dielectric strength. As it is a thermal insulating tape, It suits high-temperature applications. Whereas PVC Tape (polyvinyl chloride) is more flexible. PVC Tape is preferred in low-temperature environments but lacks fire resistance. Choosing between them depends on specific electrical system requirements.

Mica Tape vs. Glass Tape

When comparing them, both materials have unique advantages. Mica Tape delivers superior thermal and electrical insulation properties. In contrast, Glass Tape provides outstanding mechanical strength. It is frequently utilized in applications requiring additional support or reinforcement.

Mica Tape vs. Polyester Tape

These tapes cater to different needs due to distinct characteristics. Mica Tape withstands high temperatures and offers strong dielectric strength for electrical applications. While Polyester Tape is flexible and provides good moisture resistance in damp environments.

Mica Tape vs. Kapton Tape

These insulating tapes excel in thermal properties for distinct purposes. Mica Tape, being a naturally occurring mineral, offers outstanding electrical insulation and heat resistance. Kapton Tape, made from polyimide film, remains stable at high temperatures. Mica Tape is famous for fire resistance while Kapton Tape handles extreme temperatures.

Safety and Environmental Considerations

Health and safety concerns and environmental impact require careful consideration today. Let’s discuss some important considerations while mica mining and mica tape production.

Health and Safety Concerns:

- Health and safety come first in any project or endeavor.

- Identify and mitigate risks to protect human well-being.

- Prioritize workers’ and stakeholders’ safety legally and morally.

- Thorough risk assessments and safety protocols prevent accidents and injuries.

- Minimize or prevent accidents with regular safety training and personal protective equipment usage.

Environmental Impact and Sustainability:

- Each decision made during a project affects the environment in various ways.

- We must evaluate each step to minimize negative effects on nature.

- Using renewable materials and reducing energy consumption are eco-friendly practices.

- Implementing waste recycling programs can lessen the project’s carbon footprint.

- Green buildings and sustainable design save energy and lower operational costs.

- The pursuit of sustainability aims to fulfill current requirements while safeguarding the well-being of future generations.

Conclusion of Mica Tape’s Significance

It is a vital industrial component and offers remarkable properties with natural mica minerals. It excels in electrical and thermal insulation. It protects electrical equipment and cables, preventing short circuits. Mica tape resists high temperatures, acting as a fire barrier. It also repels chemicals, moisture, and UV radiation, ensuring product durability. It’s easy to handle and applicable to various surfaces. Mica tape serves the aerospace, automotive, power generation, and telecommunications industries. In conclusion, mica tape’s significance lies in its insulation, fire resistance, and versatility. It safeguards equipment and enhances safety in modern manufacturing.