Views: 0 Author: Site Editor Publish Time: 2025-10-31 Origin: Site

When customers buy G10, FR-4 or phenolic laminate parts they are buying predictable performance — not just glass, resin, and a drawing. The Production Part Approval Process (PPAP) is widely used to verify that production output matches design intent, but generic PPAP packs often miss the material- and process-specific risks of reinforced laminates and thermoset sheet products. This article explains exactly what a plastics manufacturer should include in a PPAP package so those risks are closed out before the customer ever signs off.

PPAP remains the supplier-to-customer mechanism for demonstrating production capability and consistency. For engineering plastics, the emphasis must shift from “did the part meet dimensions?” to “did the part keep its polymer chemistry, fiber architecture, and cure history through volume production?” The AIAG PPAP framework still applies as the structure for evidence and documentation, but the content of that evidence must be engineered for laminates and resin systems.

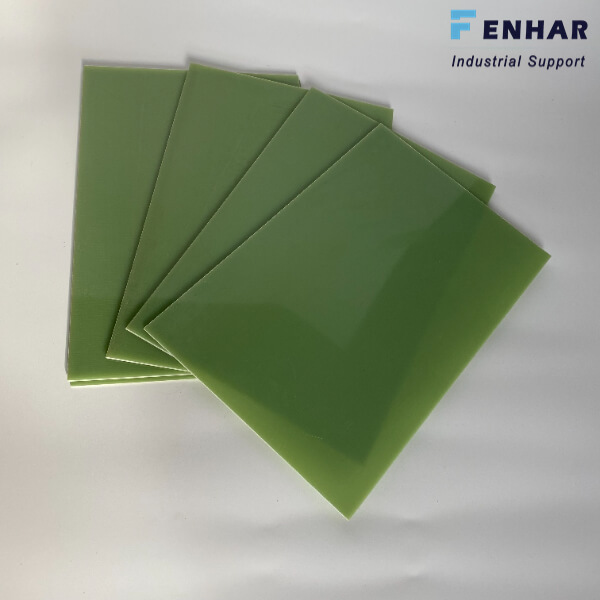

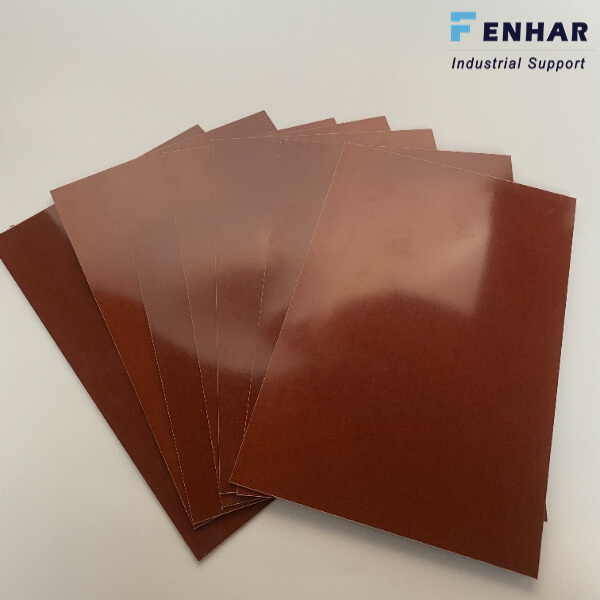

Glass-reinforced epoxy laminates and phenolic sheets are process-dependent materials: resin cure, glass weave, filler loading, and post-cure history directly set electrical, thermal, and mechanical performance. A slight change in resin lot, press temperature, or moisture content can shift Tg, dielectric constant, or interlaminar strength — changes that matter to aerospace, automotive under-hood and electrical applications. Typical datasheets show narrow property windows and specific processing notes that must be preserved in production.

Supplier lot numbers for resin, glass fabric, and any fillers or flame retardants.

Certificates of analysis (CoA) with the same lot numbers, listing resin viscosity, epoxy equivalent weight (if applicable), filler %, and presence/type of flame retardant (brominated, non-halogen, etc.).

Short narrative on how incoming material is quarantined, sampled, and rechecked prior to processing.

Why: variations in resin chemistry or filler content alter Tg, Dk/Df and mechanical strength — all customer-facing properties for these materials.

Beyond basic dimensional checks include:

DSC / TGA data showing cure and thermal stability (Tg, decomposition onset).

Electrical tests tied to application: dielectric constant and dissipation factor at relevant frequencies (use IPC test methods for traceability).

Mechanical tests: flexural strength, interlaminar shear, and water-absorption conditioned tests for parts intended for humid or wet environments.

Aging tests relevant to the customer environment (thermal cycling, fuel/chemical exposure, UV if external).

Use protocols that match the customer’s use-cases and reference recognized test methods where available.

Make the process itself an auditable product:

Clear process flow with critical control points: resin prep/impregnation, layup, vacuum/press cycle, cure schedule, post-cure, drying/storage, machining.

For each CCP provide upper/lower limits and real-time measurements (press temp/time, vacuum level, press pressure, dwell).

SPC charts for sheet thickness, density, and critical dimensions; control limits and trending for resin cure energy or Tg if in-line DSC or IR monitoring is used.

MSA for critical measurement systems (thickness gauges, dielectric test rigs, DSC/TGA repeatability).

Run at production speeds with production tooling for a defined sample size (typically a minimum lot that represents a shift or full machine cycle).

Record tool shot counts, tool wear observations, scrap rates, and any maintenance intervals triggered during the run.

Include machining trials (drilling, routing, tapping) because laminate machinability affects functional assembly and burr/delamination risk.

Examples of discrete acceptance criteria you can include in the PPAP package:

Dimensional Cp/Cpk ≥ 1.33 on critical dimensions (or per customer target).

Tg within ±X °C of the design validation batch (define X based on application).

Dielectric constant and dissipation factor within supplier-stated tolerance at the customer’s frequency of interest (use IPC-TM test references).

No delamination or unacceptable burrs after specified machining cycles.

Explicit, measurable criteria remove ambiguity during customer review.

Incoming: resin CoA, fabric lot, filler CoA, humidity/moisture check.

First article: full mechanical and electrical property suite (flexural, ILSS, Dk/Df, Tg, TGA).

Process: SPC for thickness, density, and selected dimensional features; MSA for measurement tools.

Production trials: machining test coupons, tool life, and environmental conditioning.

(Use IPC-TM-650 methods for dielectric tests and relevant ASTM methods for mechanical/water absorption tests.)

Incorrect resin lot or missing flame retardant → CoA and incoming inspection.

Incomplete cure / low Tg → process monitoring (time/temp), DSC verification.

Delamination during drilling → production machining trials, drill thrust monitoring, tool spec control.

Drift in dielectric properties → SPC on Dk/Df and supplier PPAP for any resin change.

Flammability (UL-94 classifications) and whether the flame-retardant system meets the target rating (V-0, V-1, etc.). Demonstrate test reports for the exact lamination thickness used.

RoHS / REACH declarations if required by the customer’s market.

For PCBs and high-speed electronics, reference IPC laminate specifications and measurement methods for Dk/Df as part of the PPAP package.

Part submission warrant with specific resin/fabric lot numbers listed.

Incoming material CoAs and quarantine sampling reports.

Process flow and control plan keyed to lamination and cure steps.

DFMEA with laminate-specific failure modes.

Full first-article test matrix: mechanical, thermal, electrical (list methods & labs).

SPC charts and control limits for thickness, density, and key dimensions.

MSA reports for the measurement equipment used.

Production trial report with tool counts, machining observations, scrap logs.

Regulatory test reports (UL-94, RoHS/REACH declarations, IPC references).

Change control procedure that triggers requalification on resin or fabric supplier change.

For laminates, include at least one production-scale press run plus machined parts representing normal finish operations; for critical applications, include multiple lots spaced over time (e.g., 2–3 lots) to show stability.

Provide raw test data, not just summaries — customers and labs want to see the curves (DSC traces, TGA, dielectric sweep) as part of the submission.

Call out any discretionary allowances (e.g., a machining allowance or burr limit) in the workmanship spec so acceptance is unambiguous.

Well-constructed, material-focused PPAP packages reduce back-and-forth with OEMs, reduce field surprises, and make your repeat business more likely. For engineering-plastics makers, PPAP is not just paperwork — it’s a customer guarantee that the chemistry, fiber architecture, and process history that deliver the advertised performance will be preserved when production ramps.