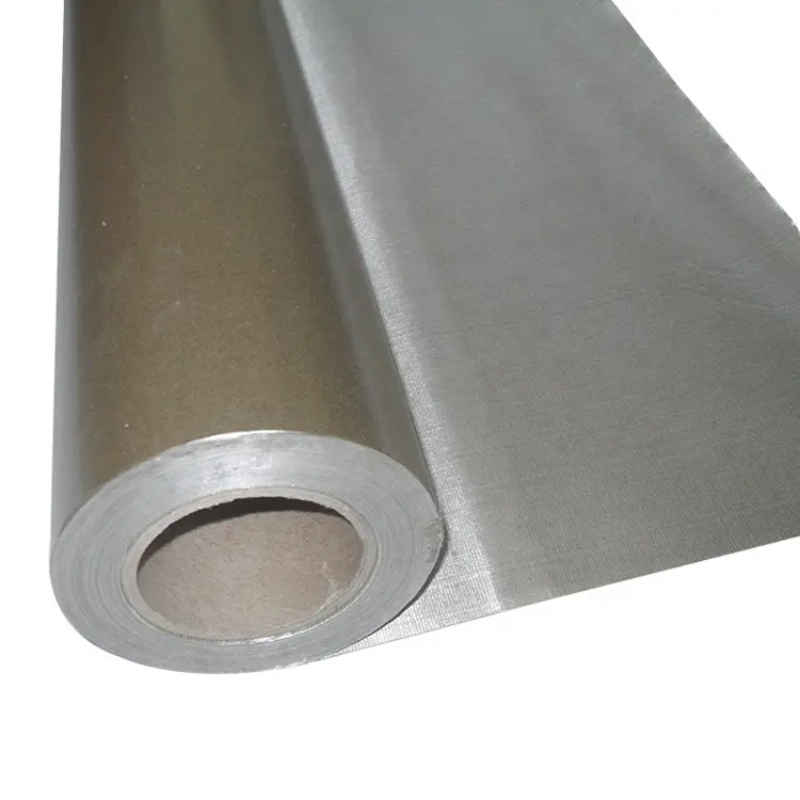

Mica Roll Overview

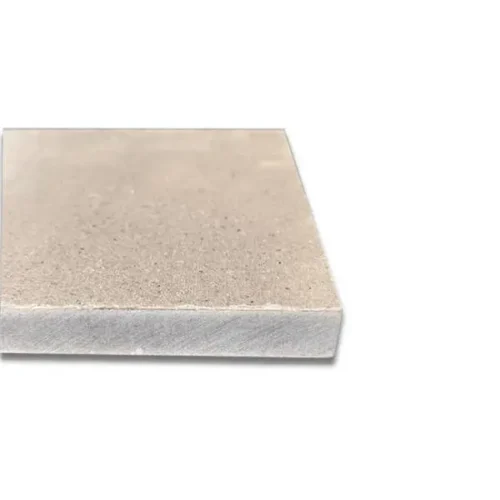

FENHAR Mica Roll/ Mica Slip Plane materials, available in roll or sheet form, are specially manufactured mica products.The thickness ranges from 0.2mm to 2.5mm, with a tensile strength above N/15mm. These materials exhibit exceptional temperature resistance, exceeding 800°C and even reaching above 1000°C.

Type of mica roll

- Phlogopite mica roll: Made from phlogopite mica, this type of mica roll offers excellent thermal resistance and electrical insulation properties.

- Muscovite mica roll: Constructed from muscovite mica, this type of mica roll provides good electrical insulation and heat resistance.

- Synthetic mica roll: Manufactured using synthetic mica, this type of mica roll offers consistent and reliable performance with enhanced thermal and electrical properties.

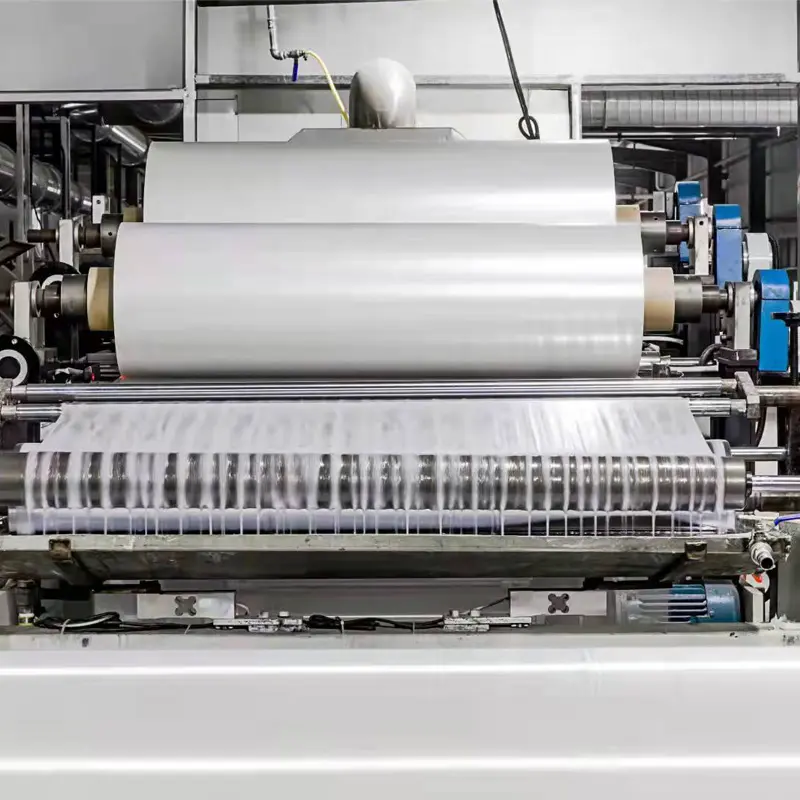

- Composites: Mica rolls may also come in composite forms, combining mica with other materials like glass fiber cloth, silicon resin, or specialized layers to provide additional properties such as improved strength, thermal conductivity, or resistance to corrosive substances.

Features and Benefits of Mica Slip Plane….

- Excellent insulation properties: Mica slip plane exhibits outstanding insulation capabilities, ensuring effective electrical insulation in various applicationstemperatures.

- Corrosion resistance: Mica slip plane demonstrates excellent resistance to corrosion, protecting against damage caused by chemicals or harsh environments.

- Chemical stability: It maintains its stability when exposed to various chemicals, making it reliable for applications that involve contact with corrosive substances.

- Versatile form: Mica slip plane is available in both roll and sheet forms, offering flexibility in application and installation

- Low smoke emission: Mica slip plane emits minimal smoke when subjected to heat, contributing to improved safety in fire-prone environments

- Impressive heat resistance: Mica slip plane maintains its structural integrity even in high-temperature environments, ensuring reliable performance.

- Convenient lightweight design: Despite its remarkable properties, mica slip plane remains lightweight, facilitating easy handling and transportation.